Cereal/Grain

Today’s grain users demand more when it comes to quality, safety, and uniformity. In addition, they seek solutions that can rapidly measure a wider variety of parameters.

Mätt Solutions with PerkinElmer have solutions that help the grain industry in its quest to feed the world. Our testing and analysis solutions cover three areas required for complete knowledge of grains and their derivatives – composition, functionality, and safety. Our analytical technologies help farmers, traders, and processors get the most value from grain at each stage, from farm to consumer. Whether the focus is moisture, protein, oil, fibre, or other components, we have the analytical solutions to meet your requirements.

- Farmers use our systems to optimize grain drying and know its value prior to delivering to the elevator.

- Elevators use our instruments for grading to avoid taking in subquality grain, for segregation to obtain optimum value, and for load-out verification.

- Processors use our solutions to verify incoming grain quality, blending/segregation, in-process monitoring, and quality verification at load out. Additionally, our mycotoxin solutions are used at all stages to help keep dangerous material out of the grain trade and processing streams.

No one wants to pay for water so moisture content impacts grain value throughout the supply chain.

- Farmers need to know that their crop is dry enough to harvest to avoid having to dry crops as the drying process costs money. This means accurate moisture readings play a primary role in profitability at each grain transaction.

- Traders and grain stores must ensure the correct moisture content or risk losing entire silos to mould or degradation.

Mätt Solutions have a variety of moisture testing solutions; handheld on farm Wile 55, Wile 78 or Pfeuffer HE 50. Receivals / on farm whole grain NIR PerkinElmer IM8800, wholegrain / flour NIR IM9500 and millers / feed mills often utilise the DA7250 offline or DA7350 / DA7440 inline solutions

Grains are often valued on protein or oil which accurately set the price of a load of grain. Fast measurement is often critical as the transporters need immediate feedback prior to offloading. Mätt Solutions with PerkinElmer offer NIR wholegrain instruments providing multicomponent results in seconds – often with comparable results to lab tests that can take 2-5 days or more. Grains are key ingredients in all kinds of food and animal feed. Animal feed is often formulated with least-cost in mind meaning the formulation constantly changes based on the prices of protein sources. This creates the risk of nonoptimal nutrition as different animals, and different ages of the same animal, require different levels of amino acids. Grain companies who can provide this information to their companies have an edge over the competition.

Grain and grain derived products are often primary ingredients in different foods. Wheat flour is a good example – it’s a key ingredient in cookies but also in cakes. This diversity means that not only is it necessary to know flour composition, but also its functionality – how it will perform in a mixture of ingredients when baked – must be well understood. PerkinElmer flour and dough-testing systems like the RVA and DoughLab can provide the information necessary to create the products your customers want.

Mycotoxins are produced by mould. Regarded as some of the most carcinogenic substances known to man, they are also hardy and difficult to manage. They can survive the fermentation process at an ethanol plant and can be at even more concentrated levels in the Dried Distiller’s Grains by-product. Mätt Solutions have solutions to test for mycotoxins including quantitative screening using lateral flow test strips in a field or elevator or in a lab using ELISA kits. We are specialists in PerkinElmer as well as Eurofins Technologies kits.

“Safe” depends on a variety of factors including length of intended storage and temperature during storage. 14.5% moisture is generally acceptable depending on these factors.

Wet weather during harvest may result in grain and seeds being harvested at higher than ideal moisture contents. Research indicates that seed moisture content (SMC) is directly related to the ambient humidity of the air which surrounds the grain or seed either in storage or the field. Taking barley grain as an example, to achieve 14% SMC the air that surrounds the grain must be 70% relative humidity or less (either in the field or during grain drying).

Grain that is warm when it goes into storage fosters the growth of mould, pests and sprouting. <20°C usually regarded as a good benchmark, the lower the better.

Applicable Instruments

-

NIR Analyzer - Inframatic 9500

Analyses grains and oilseeds in less than one minute

-

NIR Flour Analyzer PerkinElmer - Inframatic 9520

NIR for analysis of flour and semolina.

-

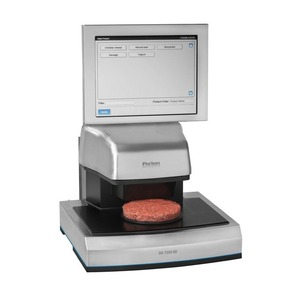

NIR Analyser - DA 7250

Quick NIR analysis for any types of samples, IP65

-

DA 7300 - NIR Analyzer

On-line instrument continuous analysis of moisture, protein, fat and more

-

NIR Analyzer PerkinElmer DA 7440 On-line NIR

Measures moisture, fat, sugar, flavorings and more in real-time

-

PCSTestr 35 Mutliparamter Tester

pocket size tester measures that five parameters (measures pH, Conductivity, TDS, Salinity and Temperature)

-

Pawkit Water Activity Meter

Pocket-size and portable water activity instrument.

-

Water activity meter - Aqualab Series 4TE

Fastest most accurate water activity meter

-

Aqualab Vapour Sorption Analyser

Allows you to measure both DVS and DDI isotherms on your product

-

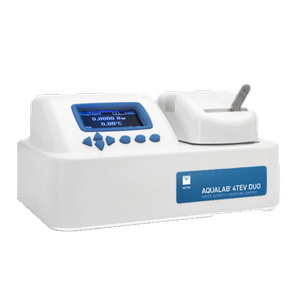

Water activity meter - Aqualab Series 4TE Duo

Can measure water activity and get moisture content simultaneously from a single sample

-

Falling Number 1000

Determination of alpha-amylase activity in grain and flour

-

RVA - Rapid Visco Analyser

Ingredient Performance Analyzer

-

PerkinElmer doughLAB - Flour Milling

Determines water absorption of flour, dough development time and other dough mixing parameters

-

Grain Truck Spears

allow the sampling up to a depth of 2 m

-

WILE 27

Moisture meter for hay, straw and silage.

-

WILE 26

Digital moisture meter for dry hay, silage and haylage.